Bangladeshi RMG workers are less paid

Photo: http://www.labourbehindthelabel.org/

Photo: http://www.labourbehindthelabel.org/

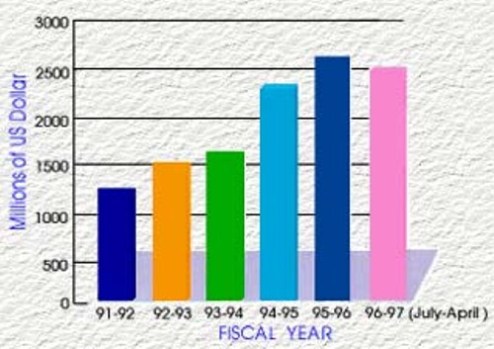

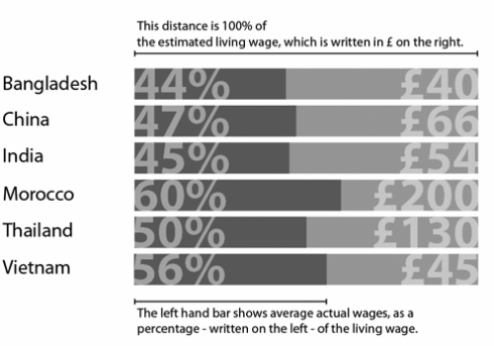

As it has been mentioned in my many write-up that our garment workers are working inhumanly from morning to evening ,doing overtime to meet their two square a meal, their wages have remained from minimum 950/- to 1650/-. There has been demand from these workers to increase their wages to a level so that they can lead a better life; so far all their demands have gone unheeded. RMGEA are talking big; they are talking about ration, an increase in their wages in keeping with the existing market price and what not. These are all hollow hopes. The statistics show that the wages of Bangladeshi worker is 40pounds i.e. 44%, China 66pounds i.e. 47%, India54 pounds i.e. 54%, Morocco 200ponds ie60%, Thailand 130pounds i.e. 50% and Vietnam45 pounds i.e. 56%. The so called big shot people must take up the matter seriously before it gets too late to keep Bangladesh RMG industries in track and keep on earning the foreign currency for this poor country which depends a lot on this sector.

Bangladeshi garment products

Photo: http://www.thedailystar.net/

Photo: http://www.thedailystar.net/

Since the creation of Bangladesh one sector in which it has made appreciable achievement is its garment industry. Any Bangladeshi can boast of its garment products. It not only caters to our requirements but also our products are exported to different countries which earn about 76% of the total foreign currency it earns. Our products are highly acclaimed by the foreigners for its qualities and verities. As our products are produced at cheaper rate in comparison to other exporting countries the foreign byres evince a lot of interest in our products and invest quite remarkably than any other countries. It is very interesting to see and one can understand from the fact that foreigners visiting our countries are found loitering specially around our Bangabazar to buy the garment products. These are the products are directly brought from the factories and are sold at cheap rate. Here both our local people and foreigners are usually seen buying the garment products produced locally.

It is very unfortunate that some unscrupulous business man change the brand of the products and want to sell the products in the name of product of foreign made for higher price, which not only destroys the goodwill of our garment industries but also put the export of our garment products at risk.

Lack of standard machine in our RMG industries

Photo: yaleglobal.yale.edu

Photo: yaleglobal.yale.edu

Anybody visiting any of our garment factories, the first thing they will encounter is the machine-the sewing machine, knitting machine and other machineries-with help of which our workers produce readymade garment products from which our country earns a major chunk of foreign currencies. Has anybody ever gone deep into the facts that the garment products which are being produced with the help of the machineries are in what state and what special efforts and the time our workers have to give to make it worthy of making it of exportable standard. It is often seen in many factories the workers are using their hand instead of using the machine, stitching, fixing buttons, which results in poor quality and defects of our readymade garment products. In most of the factories there is theft cases of parts of machines and these are replaced with low quality parts or made from lathe machine to keep the machine operational. As such the products which would have been produced with a great precision and less time, reducing extra burden on our garment workers has a great negative impact on our RMG industries. To achieve better output the first thing that the owners have to ensure is to provide flawless machineries. The owner instead of going harsh against the workers must try to find out the real causes of low quality products and time wastage factors if they really want to bring qualitative changes in their products.

Power crisis and our garment industries

Photo: http://www.aliciapatterson.org

Photo: http://www.aliciapatterson.org

Bangladesh is suffering from acute power crisis since a quite long time without any respite. The present new Government which has put this problem in the priority list has so far not given proper direction as to what steps it has taken to mitigate the crisis. The crisis has deepened to such an extent that general people started to think that we should start practice of leading life of medieval ages. One understands what role power plays in making of a nation. The major concern that is going through the minds of general people is, will we be able to keep our industries alive specially the Garment industries which brings big chunk of our foreign currency? So far nothing appreciable has been done – except meeting and hope that power will be supplied uninterrupted in next three to four years. If this state of power supply goes on for one to two years imagine what will be the fate of many garment factories. Production will come down drastically: it will start loosing the international market and lastly and most importantly the undesirable cut in workers which will be a economic disaster for the nation. The crisis can be averted if Government start thinking without further delay of importing power from neighboring countries which are self sufficient in energy .and installing burger mounted power plant on short term basis as there is uncertainty of availability of gas on which the power plant of our country depends. There has been a lot of negligence in this sector. People don’t want to see any further negligence. The Government must put in their best efforts to solve this problem as soon as possible before it gets too late to incur the wrath of the general public and the RMG workers especially which may not be good taste for the Government.

Garment workers entertainment time

Photo: http://www.proxied.changemakers.net/

Photo: http://www.proxied.changemakers.net/

Garment workers are work very hard. They work for a long time. 90% of garment workers are women so they don’t get the chance of going market or Movie Theater to watch their favorite movie for their entertainment after their work or at night. Because it is not safe for a women that she go to market or Movie Theater alone at night. And of course after a long time work they get tired so they don’t have that energy to go anywhere for their entertainment. So in the weekend especially the girls who live in the hostel they get the opportunity to watch a movie from 3 to 6 pm on BTV. Because in the hostel there is a television for all hostel girls. The garment workers actually not only the garment workers the village people love to watch Bangla movies. I heard that maximum of the hostel girls sit together in the television room and enjoy the movie on weekend. I think this is a really good way of garment workers entertainment.

RMG factories and the accommodation facilities

Photo: http://www.proxied.changemakers.net/

As most of the garment workers come of the poor family and comes from the remote areas and they have to attend to the duties on time, these workers have to hire a room near the factory where four to five huddle in a room and spend life in sub human condition. For four to five workers there is one common latrine and a kitchen for which they have to pay from Tk=2000 to Tk=2500/-.They share this amount among themselves to minimize the accommodation expense. One cannot believe their eyes in what horrible condition they have to pass out their time after almost whole day of hard work in the factory. After laborious job they come into their roost, cook their food and have their dinner or lunch in unhygienic floor or bed and sleep where they take their food. They share the single bed or sleep on the floor. The owners of these factories must not treat the workers as animals. The owners of these factories who drive the most luxurious car and live in most luxurious house do ever think that these are the workers who have made their living so juicy. Will these selfish owners ever think of these workers of their better living for the sake of humanity by providing better accommodation for these workers in addition to providing with the job.

Some garment workers live in hostel

Photo: proxied.changemakers.net/

Photo: proxied.changemakers.net/

The garment workers are come from village that’s why they don’t have any house their own in the city. They live in slum or some time they live in hostel, especially who don’t have any relatives in the city. In the hostel one girl share her room with other two or three girl. There is two or three bed inside the hostel room. Those beds make the room congested. But still they have to stay here because they don’t have any other option for staying. The garment worker who stay in the hostel actually they prefer hostel because of safety. I heard that some time they fight with each other for some reason and one of them leave the hostel. Actually the main reason of fighting between the hostel girl is – room sharing. In my point of view, I think it is really painful to share your room with unknown person.

The unwholesome environment and lack of safety measures of garment workers

Photo: http://www.ehponline.org/

Most of the garment factories in our country lack the basic amenities where our garment workers sweat their brows from morning to evening to earn our countries the major portion of our foreign exchange. Anybody visiting the factory the first impression he or she will have that these workers are in a roost. Improper ventilation, stuffy situation, filthy rooms are the characteristics of the majority of our factories. The owners profit are the first priority and this attitude has gone to such an extent that they do not care about their lives. How many of our factories have facilities to combat any hazard like fire? Are these workers properly trained to face the situation in the event of such hazard and what to do instead of getting panicked? There has been lot of such cases in recent years which resulted in lot of deaths of these workers. Countries like China, Italy give first priority of workers comfort and the safety so that they can get better out of this workers.in our countries most the workers get sick. So the time has come to improve their working environment and their safety without further delay if we are to expect uninterrupted

The training of garment workers

Photo: http://www.ypsa.org

There is no alternative to training to any types of work in order to train up the worker to fit in the job for which he/she has been employed. Most of the garment workers who work in many factories are not that skilled to do the job as required by the management; as a result in most cases the product produced are of inferior quality. Although there is demand of our garment products in the world, the demand would have been much higher if our products are produced with precision. To bring that precision the BGME must create training institution where for the workers whose 90% are young women, must be made mandatory to get admitted into the training institution for at least three months in their respective field for which they want to be employed. It is only then we can expect our products will be highly appreciated and ordered at a price higher than the prevailing price which means more foreign exchange for our country.